High-salt wastewater recycling

High-salt wastewater recycling

High-salt wastewater recycling

High-salt wastewater recycling

High-salt wastewater recycling

Return

Cycling Utilization of High-salt Wastewater

1. Water Quality

Wastewater,which is a complex of regenerating wastewater of resin and extraction wastewater in the workshop, has a high content of salt. The details of water composition are as follows.

Parameter | (mg/L) | Cl- | F- | SO42- | Ca2+ | Zn | Cd |

Feed index | Wastewater | ≤12g/L | ≤1000 | ≤22g/L | ≤1200 | ≤2000 | ≤200 |

Discharging index | Secondary low-pressure RO contributing water | ≤40 | ≤0.5 | ≤50 | ≤3 | ≤0.5 | ≤0.05 |

2. The Process Principles And Instructions

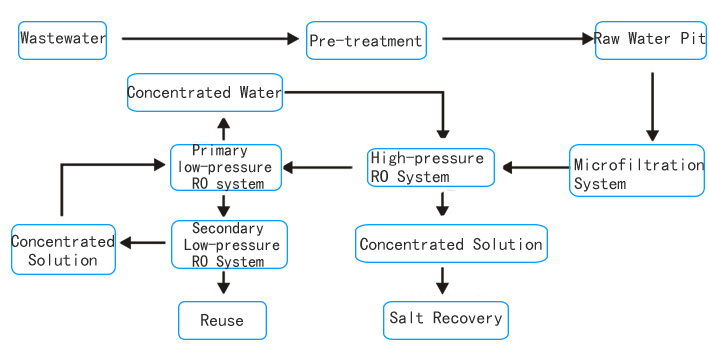

The extraction wastewater first goes through pretreatment to remove oil in the existing wastewater, and goes into the integrated wastewater treatment equipment with resin regeneration wastewater. Because of a high calcium content in the wastewater, the calcium is removal firstly and followed with filter pressing. Then, the solution is transferred to the microfiltration system to remove suspended solids, and the product water that fulfill the high-pressure reverse osmosis system standard is concentrated and returned back to the front stage to conduct the impurity removal process.The solution is transfer into the high-pressure reverse osmosis system for high concentration, and the high-pressure RO concentrated solution is subjected to subsequent processing. The high-pressure RO dialysate enters the primary low-pressure RO treatment, and the concentrated solution returns to the high-pressure RO system for processing. The dialysate enters the secondary low-pressure RO process, and the concentrated solution returns to a low-pressure RO system. The reverse osmosis membrane optimized combination treatment process is adopted, so that the treated wastewater can realize separation between salt and water. The salt is recovered as by-product, and the final dialysate is acquired to meet the recycling standard and reused in production.

3. Analysis of Operating Cost

Water inflow: 300m³/day

Working hours: 22 hours/day; 330 days/ year

Water yield: 180m³/day

Annual water yield: 59,400 m³

Direct operating cost: 297,000 yuan/year

Unit processing costs: 5 yuan/m³